ARMORING VEHICLE PROCEDURE

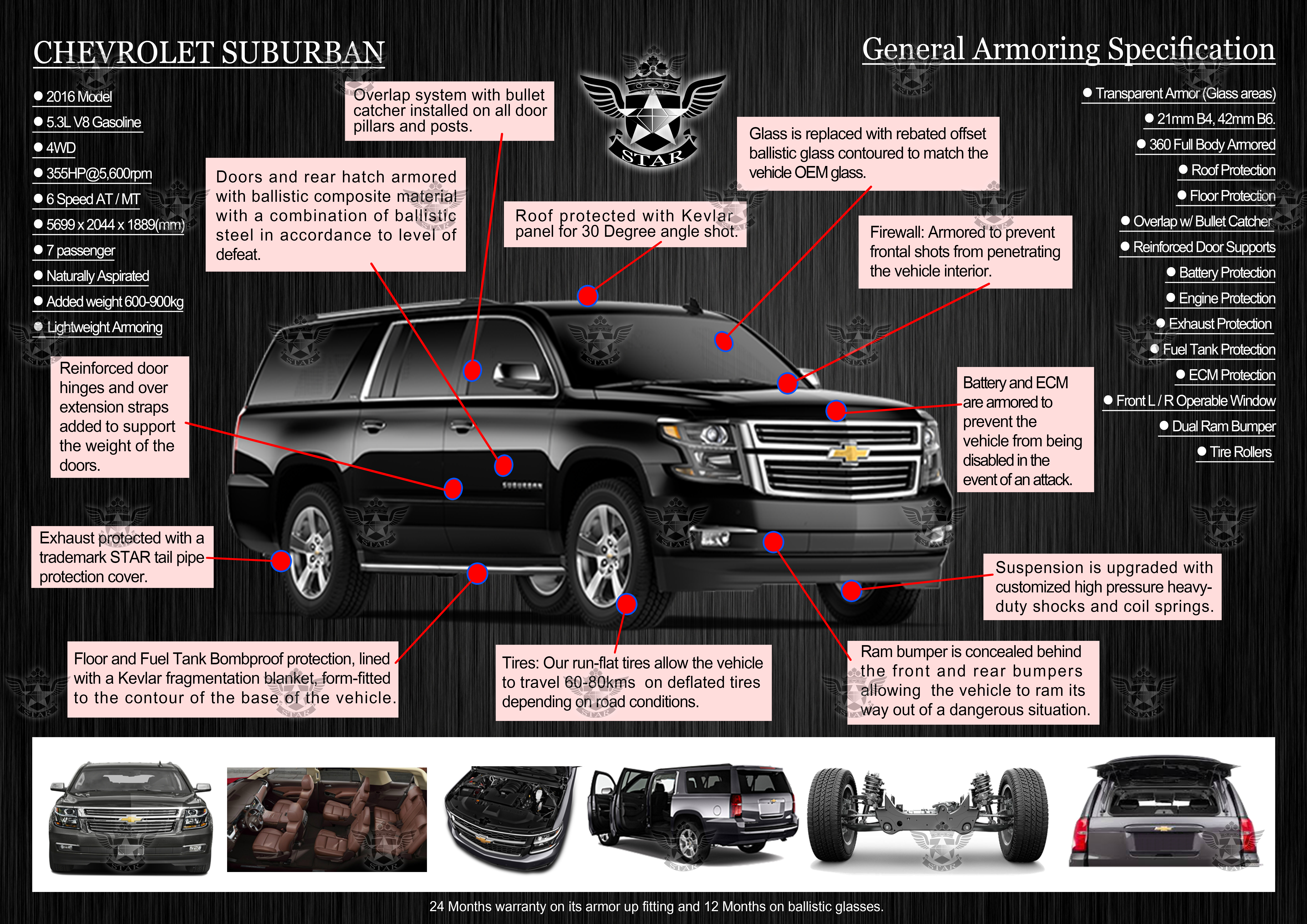

The purpose of armoring a vehicle is to protect the passengers,

not necessarily the entire vehicle itself.

Towards that end, STAR MOTOR ARMORING TECHNOLOGIES INC. provides different security packages that can help negate any threat an individual may face.

handgun protection up to high powered rifle protection.

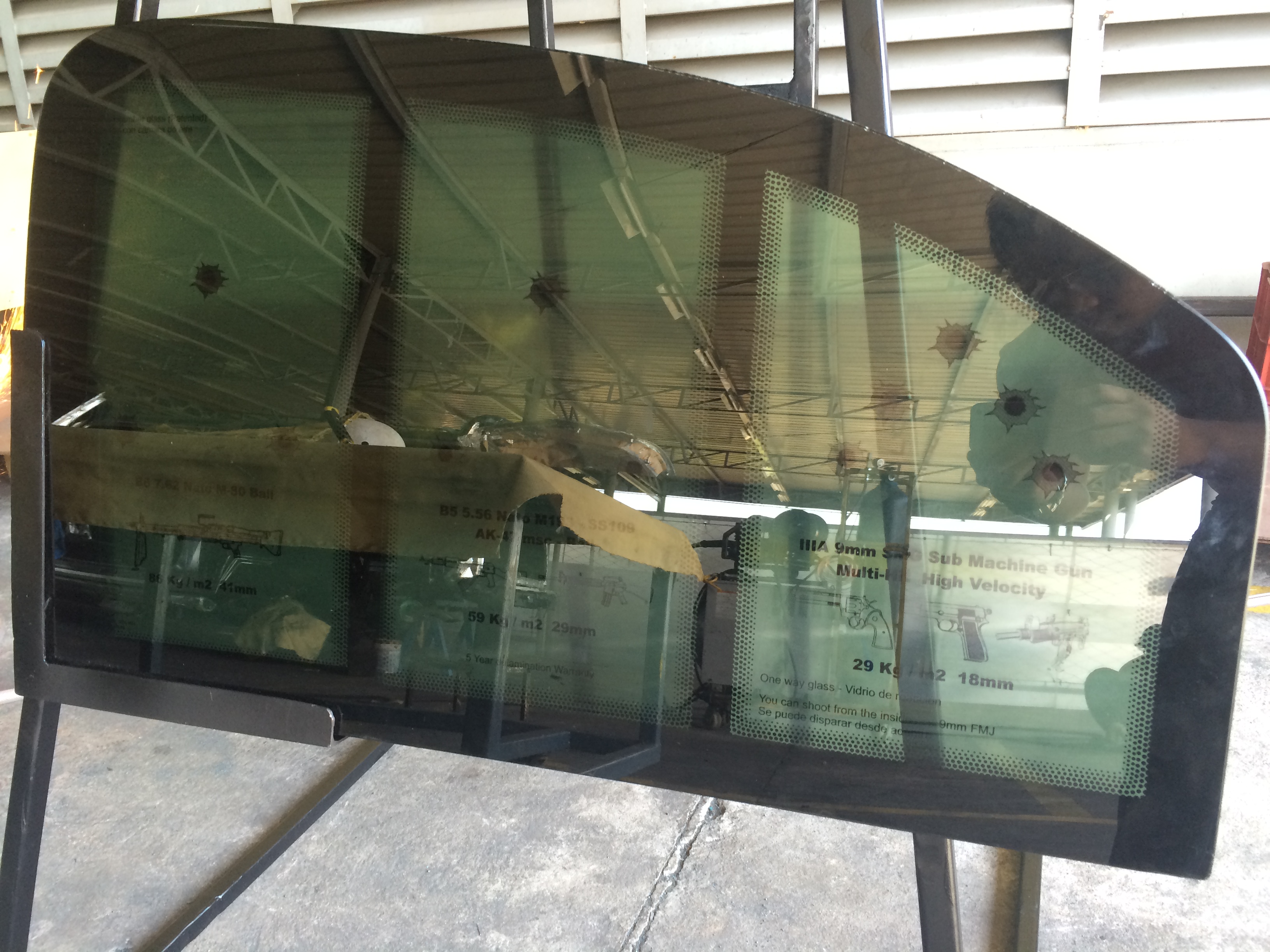

We use ballistic rebated offset glass that match the OEM glass of the vehicle.

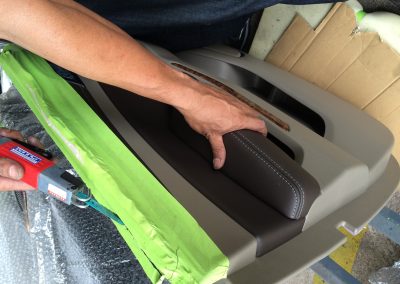

Lightweight armoring kits are installed,

thus providing maximum protection coverage

depending on our client’s needs.

PHASE 1: INCOMING INSPECTION

Interior and Exterior condition

Mechanical, electrical and performance

Measure incoming weight and height

Filing and Documentation

PHASE 2: KITS PREPARATION

Armoring kits are assembled in our facility and ballistic resistant glass are imported from the supplier of choice.

PHASE 3: KITS PREPARATION

PHASE 4: ARMORING THE VEHICLE COMPONENTS

FROM FRONT TO THE REAR, TOP TO BOTTOM, INSIDE AND OUT.

PHASE 6: COMPLETED VEHICLE

Exterior – Interior Photo, Quality Control and Inspection

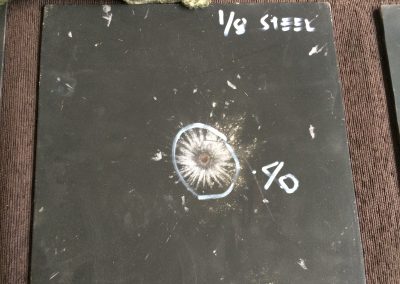

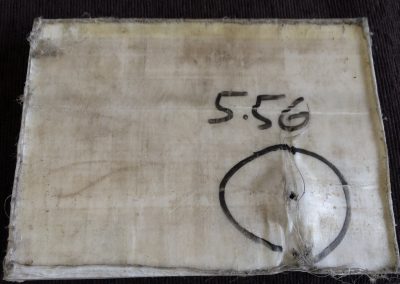

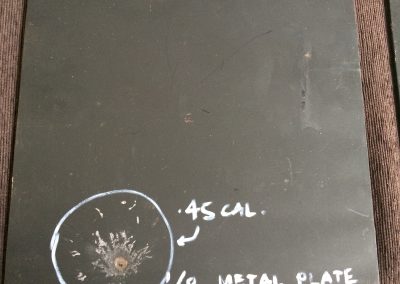

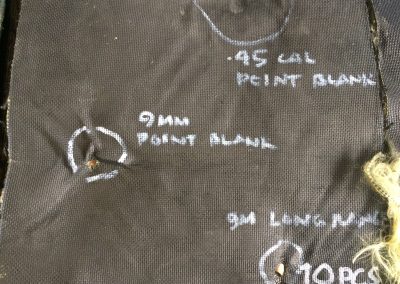

Ballistic Test

Opaque and Transparent Armor is comprised of many different materials.

We implement the most cost efficient and lowest weight solutions for Private Armored Passenger Vehicles.

Vehicles armored with lightweight armoring kits will have an increased life,

maintainability of original performance and less of the service issuescosts commonly associated with heavy, steel armored vehicles.

SEE OUR WORKS.

CONTACT US

Address

#2272 Pasong Tamo Extension Makati City, Philippines

Star Motor Armoring Technologies Inc.

sales@starmotorarmoring.com

Contact Numbers

Telephone (02) 624-1688

Globe 09171243555

Smart 09493305197